Product description:

top work roll chock(operate side)

top work roll chock(drive side)

bottom work roll chock(operate side)

bottom work roll chock(drive side)

material: forged 1045 steel(45 steel)

Application:

Rolling mill stand equipments.

Rolling mill work roll chock is one of the important parts of rolling mill , they directly bears the working rolls load.

The rolling force is transferred to the chock through the bearing, so whether the roll chock structure of the rolling mill is reasonable and whether the accuracy meets the requirements will have an important influence on the service life of bearing and the safe operation of rolling mill. The rolling mill blocks bears large load and has complex structure.

High precision requirements, long manufacturing cycle, easy to deform processing, is the focus of many professional manufacturers.

Application

The chocks are the essential components for various rolling mill like cold rolling mill, hot rolling mill, section rolling mill, cold strip rolling mill, hot strip rolling mill, seamless tube rolling mill and etc.

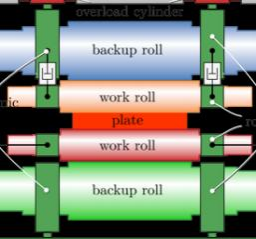

We broadly categorize chocks into 4 types, including top back up roll chock, top work roll chock, bottom work roll chock, bottom back up roll chock.

Material for chocks: depending on client's requirement, could be forging or casting parts;

We supply customized engineering and manufacturing service, one stop service manufacturer for non-standard parts for metallurgicl industry!