Product description:

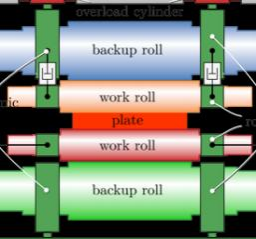

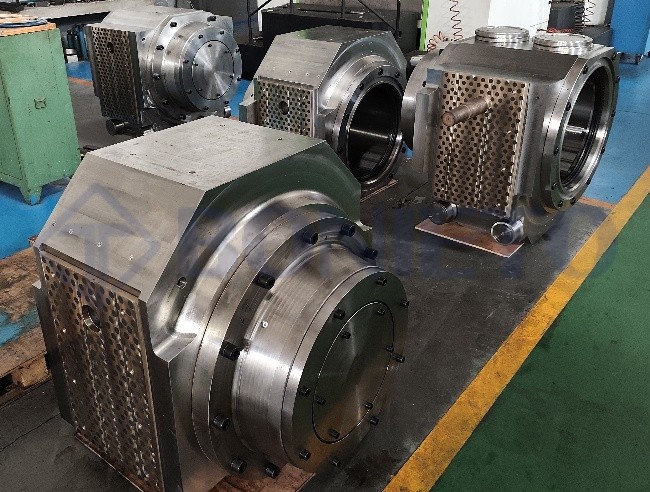

work roll chocks

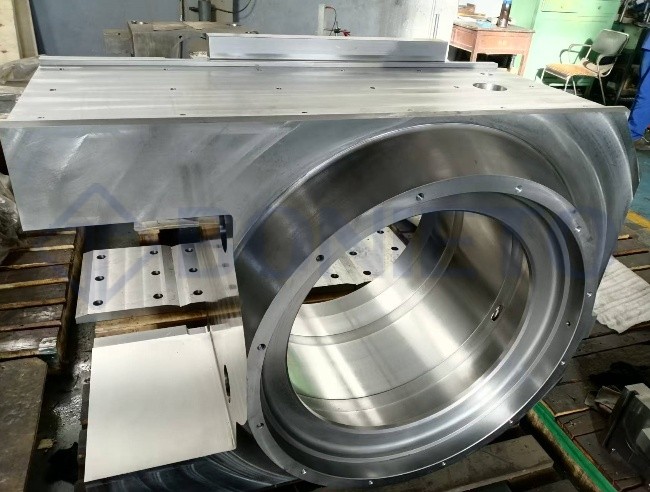

back up roll chocks

Application:

Rolling mill stand equipments.

Rolling mill back up roll chocks are one of the critical parts in a rolling mill. They directly bears the load from the back-up rolls and play a key role in transferring the rolling force through the bearing.

Therefor, a well-designed chock structure and high manufature accuracy are important for extending

Application

Chocks are essential in various types of rolling mills, including:

-cold rolling mills;

-hot rolling mills;

-section rolling mills;

-cold strip and hot strip rolling mills;

-seamless tube rolling mills;

We broadly categorize chocks into 4 types:

Chocks mateiral can be forged or casted, depending on clients requirment.

We supply customized engineering and manufacturing service, one stop service manufacturer for non-standard parts for metallurgicl industry!

We also manufacture mandrels & spare parts, tension reel, payoff reel; These products are widly used in steel and non-ferrous metals industry, such as cold rolling mill, continuous picking line, galvanizing line, color coating line, slitting line, etc.

Contact us to find your solution!