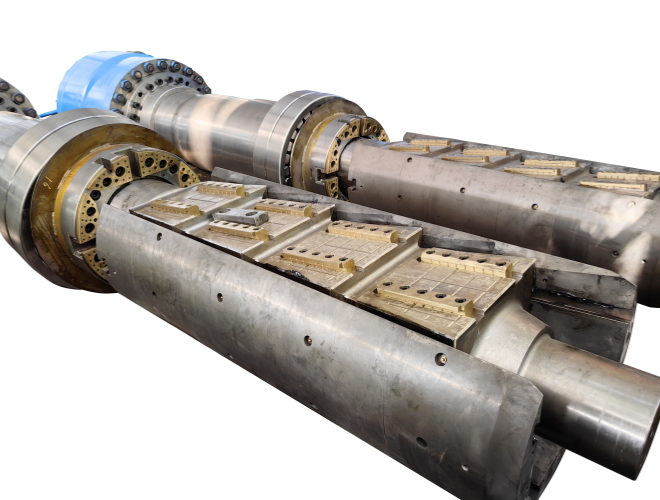

Our featured products: steel strip cold rolling mill tension reel mandrel assembly with large tension, and maximum tension 50T.

Such assembly mandrel shaft application: steel strip rolling mill tension reel. The mandrel shaft is pyramid structure, with S218 bronze overlay; The tension of this mandrel maximum is 50 tons.

The mandrel has its own independent hydraulic gripper, through the hydraulic system,realize the expanded and collapsed and the clamping and opening of the gripper. This structure of the mandrel has good strength, rigidity, good precision, high tension, high speed and heavy bearing capacity, etc.

The main components of the mandrel are: pyramid mandrel shaft, segments, hollow shaft, gripper,gripper segment, gripper hydraulic cylinder, expansion and contraction cylinder, rotary joint, outboard bearings support.

The main process flow is as follows: raw material forging - rough processing - ultrasonic test- quenching and tempering - semi-finishing machining- aging - finishing machining - nitriding treatment, etc. The segment plate and the pyramid shaft pass through the nitriding hardness difference to increase the wear resistance of the product.

We devoted to provide high precision mandrels, tension reel, payoff reel and other non-standard spare parts for flat metals rolling mill and coil processing lines. We could independent design, manufacture and assembly this type of mandrel shaft, contact us to find your solution!